Stop the SHOCK with W-Technologies Hydraulic Shock Dampers

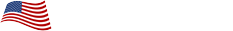

W-Technologies Hydraulic Dampers designs and builds a line of standard hydraulic shock dampers that when installed in blanking process can eliminate the break through shock. Need a Solution for Press Noise Reduction?

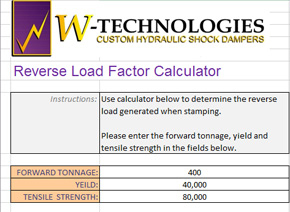

Our shock dampers are designed to provide a counter pressure force, upward, at the moment of part breakthrough. Properly sized and adjusted, our shock dampers will eliminate the reverse load or tonnage during blanking. They will also allow you to increase your blanking capacity (tonnage) on each press that has dampers.