Request for Quote

Please fill in the form below to receive a prompt quote.

Please fill in the form below to receive a prompt quote.

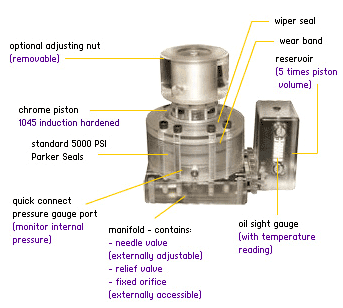

W-Technologies Hydraulic Dampers are the most versatile hydraulic shock dampers in the industry. Click here to read more about the four features offered only by W-Technologies.

As a result of technology, W-Technologies Hydraulic Dampers can be moved from press to press as easy as tooling. Without disassembling the damper, the tonnage and the speed can be adjusted to optimize the efficiency and versatility.

When cooling the hydraulic oil is required, the attached reservoir is modified with internal aluminum cold plates which allow cold water to be circulated through the reservoir from an external supply.

The implementation of W-Technologies custom hydraulic shock dampers has led to substantial noise reduction on a variety of presses. Contact us today to learn more!

Site gauge is actually located on the rear of the reservoir, but for ease of viewing, it’s shifted to the right.